enValueBiz

enSmartFactory (SmartFactory: Integrated Smart Factory Solution)

outline

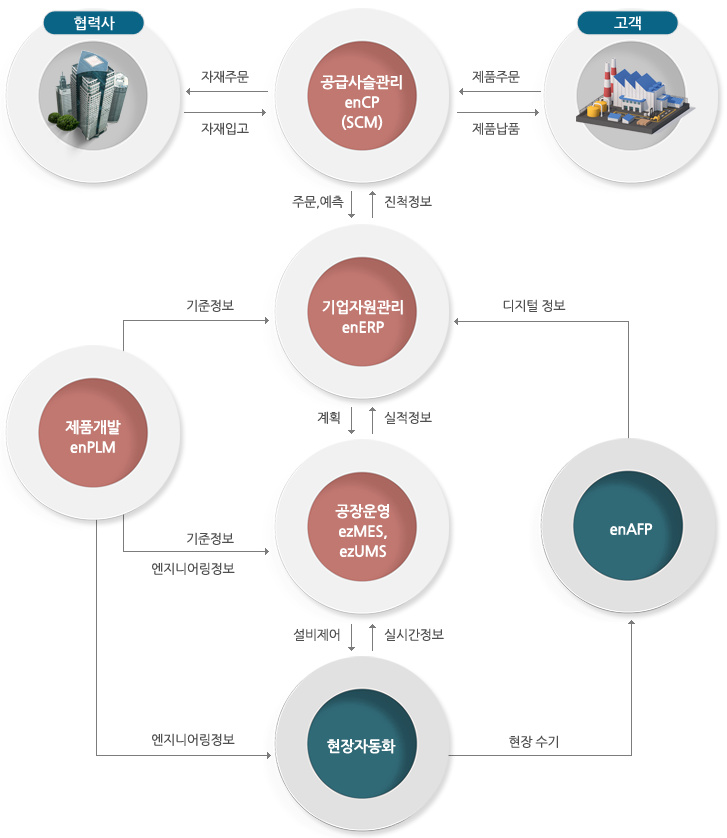

It is a total solution that provides integrated and connected smart and innovative solutions required across the entire cycle of corporate production activities, from the company's customer/partner supply chain management (SCM) to internal product management (PLM), resource management (ERP), and factory/site management (MES/UMS).

System configuration diagram

Key Features

- enCP (Capacity Planning) provides a company's planning-based operation system process, and is organically linked with ERP and MES systems to optimize demand (sales) plans and production plans linked to major SCM operation processes, maximizing productivity improvement.

- enERP (Enterprise Resource Management) comprehensively analyzes the business (accounting, logistics) processes of the entire company and reorganizes and standardizes the flow of information to organically connect organizations and information.

- ezMES (Manufacturing Execution System) manages production plans/performance, monitors real-time production status, and tracks/analyzes quality control and various production performances.

- ezUMS (Utility Management System) supports efficient factory operation by integrating and collecting all measurable data within the factory, remotely monitoring/controlling, and analyzing.

- enPLM (Product Lifecycle Management) accumulates and reuses design drawings and various development-related data, which are core assets of a company, to dramatically improve product development processes and work productivity.

- The enAFP (Auto Form Processing) solution creates a digital image copy and handwriting-recognized text data identical to the recorded content when content is written on a standardized form with a digital pen. This data is used for various management tasks through system linkage and Excel conversion.